WoodDo

Automatic wood drying system

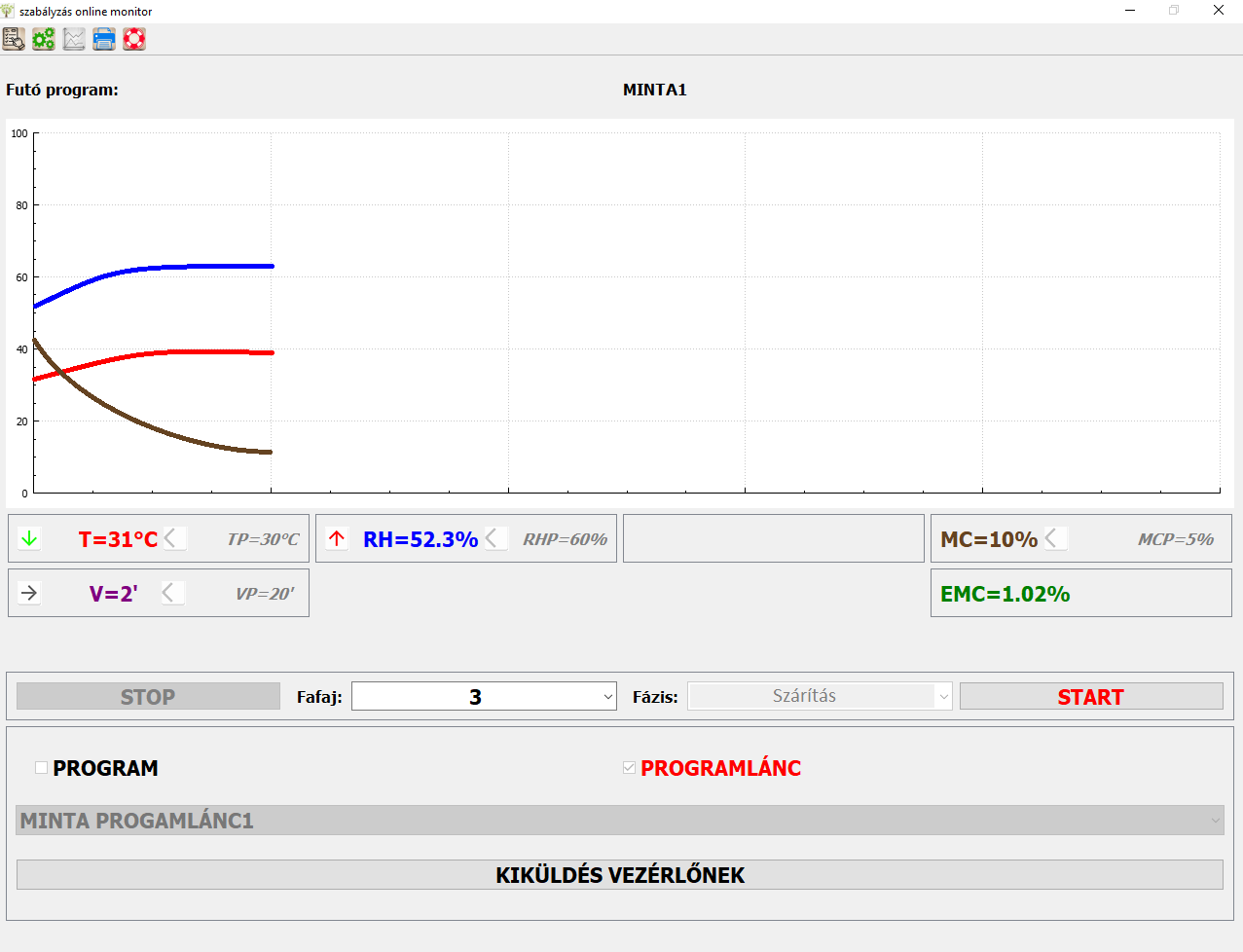

The WoodDo, wood drying system, makes the automatic drying of wood materials possible, the user can follow-up and control the whole drying process by the help of a graphical user interface (GUI) and he can interfere into the process, if needed.

We have developed different programs for the WoodDo system considering the different sorts of use:

The measurement/control system includes three sorts of unit:

- WDMC unit It is a 6-channel temperature compensated timber moisture content measuring unit, out of which you can apply 2 units wihtin one system.

- WDRHT unit It has 1 temperature and 1 air relative humidity measuring units, out of which you can use 4 units within one system.

- WDCont unit It receives the measured characteristics from the measuring units. By these characteristics it creates the basic signs of the temperature, the air relative humidity, the equilibrium moisture content (EMC), the timber moisture content and the drying factor (GRADIENT). Finally, this unit executes the controlling on the basis of these basic signs and the commended signs, created by the program downloaded on its 6 controller outputs (heating, cooling, humidification, vapour removal and controller of two rotation directions of kiln ventilators).

It is easy to use the supervisory program and the application too. During the editing of the programs the parameters fixed appear in graphical format and the user can immediately control the parameters set. The setting of parameters is also easy and the eventual user's mistakes are totally eliminated. During the drying process the actual basic signs and the values commended appear in numerical and graphical formats too.

It is easy to use the supervisory program and the application too. During the editing of the programs the parameters fixed appear in graphical format and the user can immediately control the parameters set. The setting of parameters is also easy and the eventual user's mistakes are totally eliminated. During the drying process the actual basic signs and the values commended appear in numerical and graphical formats too.